The pioneer of upvc rooftile manufacturing in Iran!

+9120465839

Sales unit Connection

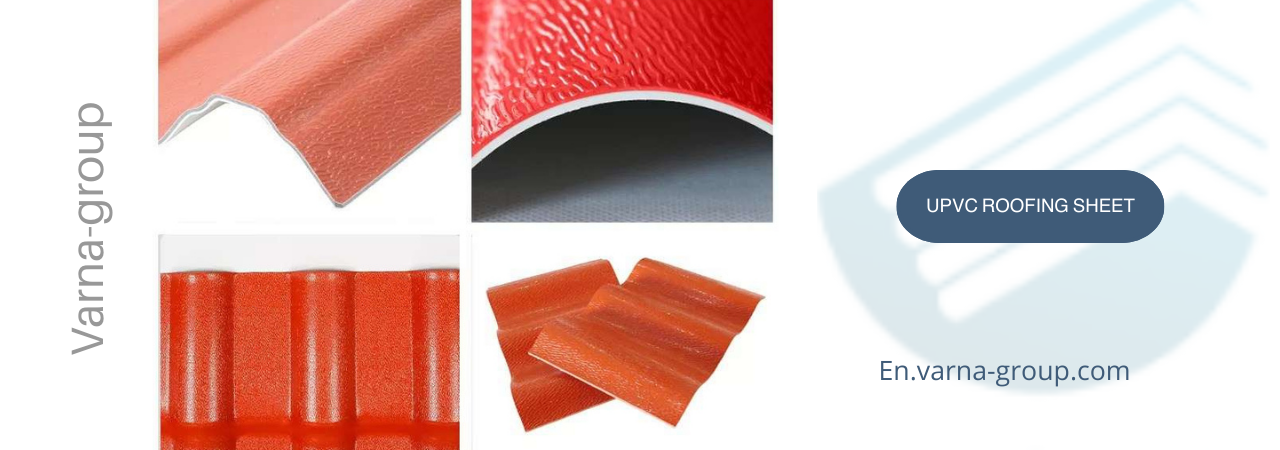

UPVC Roofing Sheet is a Multilayer durable – 2 – 3 or 4 layer – coating. It is also known as unplasticized poly vinyl chloride roofing sheet. The advanced technology of manufacturing uPVC roof sheet ensures high quality and excellent performance in the roofing systems. UPVC roofing sheet is the best replacement for asbestos, wood, metal, etc.

UPVC (Unplasticized Polyvinyl Chloride), is a low-maintenance building material used mostly for waste and drain pipes, guttering and downpipes, door and window frames, etc.

UPVC is a cheaper alternative to timber and aluminum. It is a popular material due to its durability and being a cost-effective option.

To make it, manufacturers use vinyl polymer. Chlorine atoms – which are not plastic – They work well with steel, polymeric aluminum foil and other alloys. (As good insulators and durable roof coverings). So the main material is UPVC, along with some other strengthening materials which increase its rigidity – though maintaining its flexibility. It will help to lower the cost of roof building.

Why is roofing sheets so popular? What are their advantages over other roof coverings? Here are some of the reasons:

UPVC is a versatile material that is widely used as roof coverings to resist corrosion and extreme weather condition. Whether you have a flat roof or pitched house top; UPVC roofing sheet has a large area and a good display to protect them from harsh damage.

UPVC roofing is made of multiple layer sheets. It is made of PVC – Polyvinyl Chloride – and some amount of other substances as raw material. Through advanced equipment with Co-extrusion technology processing, special production technology allows to ensure an additional margin of safety.

Multilayer uPVC Roofing Sheets

UPVC Corrugated Sheet is a great choice for roofing projects where durability of the roof and plenty of natural light – to pass through your building – is important. Both is achieved by combination of a strong uPVC corrugated shape and synthetic polymers.

Corrugation makes roofing sheets stronger, which is what you want.

Most important advantage of corrugated sheets – over flat roof sheets – is the extra strength. This amount of strength in corrugated sheets gives them additional rigidity while bending. So that prevents them from sagging. Gives them enough support and will ensure that your roof remains strong and rigid.

Expansions and contractions of the roof – due to temperature changes – can cause leakage in the roof. But UPVC Roofing Sheets that are corrugated, do not cause leak in the roof.

The structure of corrugated sheets can make enough movement for it. Therefore the sheets are not damaged due to the temperature changes.

It is generally applicable to various residential houses, villas, industrial sheds, steel structure buildings, warehouses, etc.

If you also want to know if this material is suitable for roof coating of you home or building; you can make a better decision by knowing its advantages and disadvantages.

Here are some of the advantages of uPVC sheet for roofing:

It is about 1/3 of clay tile, 1/5 of 10-millimeter thick cement tile and 1/2000 of a 0.5-mm-thick color coat steel tile.

UPVC roof covering has many advantages. However, we want to state one of its disadvantages; so that you can choose the right one for your roof – in addition to its advantages.

This type of roof sheet might not be the most economical covering in the market. It is more expensive than traditional asphalt roofs and metal roofs. However, due to its high durability, maintenance costs can be significantly reduced. So you no longer need to pay a high price for roof repairs and replacements.

Here are the steps for uPVC installation:

First you need some installation tools.

When lifting the sheets to the roof, the pile quantity cannot exceed 20 pieces.

During the installation of two-slope roof. It should be started from two slopes simultaneously, in order to keep the uPVC tile peak in same direction. Top-ridge tile is installed on the ridge line. Install from one side of the main tile. On the joint of the first main ridge tile and main tile. Overlapping should be avoided to overlap one wave-unit between two top ridge uPVC tiles.

What screws to use for uPVC roofing sheets? UPVC roof parts must also be waterproofed. While installing uPVC roofing sheets you need special waterproof accessory. It helps fix the water-leakage and corrosion problems. UPVC sheets are fully sealed with waterproofed screws.

After confirming the overlapping is correct, fix the tapping screw. Screw can only be fixed on the uPVC wave. Before fixing the screw, you need to pre-drill on the UPVC roofing sheet – not on the purlin. If the tapping screw diameter is 6.3 mm, you need to pre drill a whole of 7 mm or 8 mm.

UPVC sheeting applications are important. What can uPVC sheets be used for?

They are mainly used at roofing and wall cladding for industrial and commercial buildings. (Industrial shed roofing); like factory, warehouse, parking zone, plaza, canopies and awnings, etc.

Due to the features of anti-corrosion, they are also best recommended to areas with high humidity and chemical vapors such as: chemical factories, food factories, farming – like poultry, cattle farm, etc.

uPVC roofing sheet as better alternative of steel sheet, are being widely used.

Our Company ( Sepid Fam Varna ) uses the world latest technology in the field of UPVC sheets manufacturing. We use advanced machinery and professional experts to produce the best roofing sheets – and ship them to different parts of the world. Upvc roofing sheets buy online at Varna-group.com

Here are some of our special products in roofing & cladding:

UPVC Eco-panel or sandwich panels for roofs and walls: It is an insulated roof panel consisting of 4 layers. The first layer is anti-UV polymer alloy. The second is UPVC. The third layer is elastomeric laminated aluminum foil.

These Eco-Roof Panels can have various applications based on insulation thickness. It is more economical compared with existing conventional roofing systems.

UPVC roofing sheet thickness: 8 mm to 42 mm

UPVC roof panel length: Custom designed

Effective Width: 100 cm

Elastomeric foam insulation is a high-quality synthetic rubber, it’s a closed-cell structure that has excellent thermal insulation properties, to reduce heat transfer. Elastomeric rubber foam has low water vapour permeability that control condensation and prevents from moisture ingress – the main cause of corrosion of roofing sheets.

Insulation of ventilation in roof tiles, affects the durability of the sheets, useful for energy efficiency and comfort of people living inside the building. Upvc Elastomeric insulation has 5 main tasks:

Moisture resistance

Elastomeric foam insulation can prevent from condensation and solve leakage issue.

Excellent thermal insulation

It effectively manages heat to increase life expectancy of the uPVC roofing sheets.

Sound insulation

Closed-cell elastomeric foam insulation has specific acoustic performance. its multi-layer construction can reduce the sound effectively.

Health & Safety

Elastomeric foam insulation resists to mold, fungi and bacteria. It does not let them grow. So it creates a safe and clean environment for the residents of the building.

Durability and Installation

Flexible elastomeric foam is less susceptible to cracking and breaking. Its elastic and smooth form prevents damage to uPVC roofing sheets.

Another production that makes the roofing sheet price more economical, is our Company’s Trapezoidal roof tiles. UPVC sheets have introduced a new generation of roofing system to the market by eliminating the disadvantages of existing roof tiles.

Upvc roofing sheets specification

UPVC roofing sheet size in poly roof trapezoidal tiles can be customized depending on the applications and regions.

Polyline is a kind of construction material used in roof installation. It is made of UPVC with PU layer on top. It is available in a variety of shading colors. This product consists of 3 layers including uPVC as the bottom layer, polymer alloy both as middle and top layer that is applied on UPVC layer in 2 phases respectively. These tiles are produces in 1X2 and are easier to install compared to similar products since they do not require specific substructure.

Considering the amount of overlapping for required sealing, they can be installed on metal or wooden purlin.

UPVC roofing sheets specification

Slate roofing sheets are mostly used in pitched roofs. They are available in plain or curved patterns and can be applied in step-shaped and adjustable roof structures.

Slate roofing can be applied in villas, residential houses, window awnings, gazebos, cottage rooms, office building entrances.

UPVC roofing sheets specification

To install the slate roof and prepare the frame work, rafters should be installed.

Shingles is also used as UPVC sheets for roofing. Shingles have been the most common type of roof covering for centuries. They are used for pitched roof in the world.

They are made of different materials such as wood, asphalt, stone, cement, clay and uPVC. UPVC shingles are arranged in an overlapping manner in which each successive tile overlaps the next one – when installed from bottom edge to the top. Each 7 upvc shingles covers 1 m2 and has different thicknesses.

Shingle roof tiles are installed on OSB boards. OSB boards are arranged on metal substructure and a special sealer layer is applied on them. Then uPVC shingles are installed by screws or special nails.

Due to their shape; corrugated roofing sheets are a popular roofing material. They channel water off the roof quickly and efficiently.

Most corrugated uPVC sheets used in roofing industry are coated with anti-scratch coating and anti-uv layers; So that they remain intact for longer period of time when exposed to harsh environmental conditions.

Corrugated sheets are classified into the following categories:

Although metal roofs and plastic roofs are two popular materials in roofing industries, they have specific differences which makes them 2 completely different choices for installation. Please take note, you need an experienced roofing contractor to do the installation for you.

First we look at the uPVC roofing sheets price compared to metals. In terms of cost, metal roofing is cheaper. It costs less per square foot. Although in buying metals for roofing, its lower price leads to more satisfaction, but in long run; you will notice upvc roofing sheets are more cost-effective. It does not need much repair and it is low-maintenance. uPVC life expectancy is over 30 years.

Your roof is a critical component of your property. It has to be stable in extreme weather conditions – rainfall, winds and, high temperature changes and more. So selecting the right materials for stability of your roof coverings, is an important responsibility.

You can expect a metal roof to last for decades – with proper care and respect. But it has some very important disadvantages you need to consider before installing.

PVC roof covering can be a good choice for flat roofs, but not for pitched roofs – unlike metal covering.

What is ASA roof tile? The ASA roof tile is a Spanish style synthetic resin. ASA (Acrylonitrile styrene acrylate) is an ultra-weather resin. It resists to ultra violet rays. It has a low heat transfer coefficient. Therefore, saves energy and reduce the expenses. It is also resistant to chemical corrosion.

ASA is a polymer co-extruded made by 3 types of materials simultaneously: acrylonitrile, styrene, and acrylate. It can be made by 3 or 4 layers with co-extrusion technology.

How is PVC Roofing installed?

PVC can be mechanically attached or adhered to the roof substrate -by plates and screws.

In order to prevent from water leakage, PVC overlapping seams are heat-welded together. This way they do not break down over time like some other roofing systems. In order to bond their seams, these roofs use glues, double-sided tape, or asphalt.

Do you need insulation for suspended ceilings?

Insulation in suspended ceilings will benefit the working environment. They improve the thermal efficiency of a building and reduce the depth of ceiling height, keeping the warm air below.

Surface layer or top layer is make of high quality polymer alloy which can greatly protect the roof against weather changes, corrosion, chemical toxin UV light. This first layer prevents the sheet from aging, split, color fading, etc.

Second layer: It plays a big role in resisting to heat, sound, damp, etc. generally, quality of the insulator is determined by materials in this layer.

Bottom layer: toughness and strength of the sheet against impacts, come from this layer. It ensures longer life span of your roof covering.

Cladding is a term used in multiple coatings on the building structures. It increase aesthetic and safety of your building. You can use many materials for cladding; such as stones, metal, plastic, wood, etc. each comes with their specific features for different tastes of the customers.

What are the different Types of Cladding?

UPVC cladding is the cheapest but one of the high-quality options. It is low-maintenance. The color of the uPVC cladding can fade over time, and in harsh weather conditions. But it can be restored with little maintenance efforts.

What is the best Cladding material for long term use?

It depends on the climate and geographical condition. For instance, If you need a roof that is resistant to fire, wind, sound and water – or if you live in a cold or warm or humid climate – then uPVC cladding can be a good choice.

Roof cladding is a material that is made up of plastic or metal panels. Roof cladding is an installation process on top of the existing roof, using screws or nails. Here we want to introduce some advantages of it for industrial roofs:

Why do we use cladding in the first place? Because it provides a protective layer for the surface of our building. It also adds strength to the mechanical properties of the building. It protects it from damage caused by external environmental factors. The buildings without exterior cladding, may experience crack and damage.

Cladding protects the structures from UV light and water absorption, pollution, winds, mould, humidity, etc. Protection is the first priority in external appearance and safety of the entire building.

One of the biggest advantages of cladding a building is that maintenance effort done by cladding is less than painting costs.

Most external cladding need regular washing just to keep it new and fresh.

The cladding makes the building durable so that it can withstand harsh weather without causing much damage.

The look of the building as an aesthetic aspect of the structure, is also important. With new and modern styles – maybe in future – when you decide to sell the property, it give you a higher market value. Many options are available in the market; brick cladding, greenwood, Stone cladding, Whitestone, rustic, etc. Each of them provides a unique look to a building facade. For instance, UPVC roofing sheet and cladding is an option you might need to consider. It keeps the appearance of the building new and clean – even after many years of use.

What factors will affect the price of roof covering and installation?

The cost of installing a new roof or replacement depends on various factors. Below we will cover some of them.

Investing in high quality roof coverings not only protect your home from different weather conditions; but it also lowers your expenses on energy bills or future repairs.

Ventilation:Installing ventilation can expand the lifespan of the roof may impact your roof. It increases energy efficiency and at the same time the costs of roofing sheets. So you need to estimate the minimum ventilation of your building.

Roofs may have steep or low slopes, or a combination of both. Roof slope is a ratio that shows how many inches the roof rises vertically – for every 12 inches it goes horizontally.

So, steeper roofs, are more costly, and they are more dangerous to be installed. So they might require special equipment for the workers to use while working on it.

Your contractor will consider the architectural design and complex construction when he estimates the cost.

In both cases, a roof repair seems to cost less than replacement of the total roof.

FAQs

PVC (Polyvinyl Chloride) is durable, flexible, and is low-maintenance. It is a lightweight and waterproofing material for roof covering. It is resistant to chemicals and weather condition. It is an anti-corrosion roof covering.

UPVC (Unplasticized Polyvinyl Chloride), though it is flexible; but it is harder and more rigid than PVC roof covering. The term “unplasticized,” means: UPVC roof coverings do not have plasticizers added to its PVC material. That is why it is not that much flexible – compared to pvc roof covering.

They are durable and low-maintenance. It is an excellent heat and energy insulator. It is resistant to corrosion and high temperatures. UPVC roofing sheets are difficult to knock down. If robbery or break-in occurs, they can increase the security of your buildings – due to its high Rigidity and hardness.

Corrugated roofing sheets are lightweight and have been. They are widely used in agricultural and industrial projects. Corrugated Sheets are low-maintenance and might need repairs after around 10 years – depending on UV exposure and region.

Due to the shape of the corrugated sheets, it is a highly durable roof covering. In case of rubbing together and lack of proper care, it can easily get scratched and damaged.

Among other types of roof coverings, plastic sheet is the least preferred choice; because it is not durable enough. But it is lightweight, waterproof, anti-corrosive, highly flexible, and has an easy and quick installation. Of course, you should consider plastic sheets durability depends on the type of plastic which you use. If you want to go lightweight on your rooftop, plastic sheets are a good option.

Upvc roofing sheets or plastic sheets?

If you want more strength and rigidity, go for uPVC roofing sheets. Because they are both lightweight and durable. Plastic roof sheets don’t always guarantee durability and life span. Therefore, they may lead you to more expenses.

How long is a warranty for your roof sheets in our Company?

Warranties protect your investment in roofing system and make them perform optimally for many years.

Roof warranty cover and roof insurance in our Company is up to 7 years.

What is corrugated PVC roofing sheet application?

Corrugated PVC panels are widely used in: Car ports, industrial sheds, pergolas, stables, farm, walkways, etc.

It is used as replacement sheets for old roofs as well. (As roofing and cladding).

PVC (polyvinyl chloride) is a strong but lightweight plastic material. It it’s been softer and more flexible by plasticizers. If no plasticizers is used, then you have uPVC (unplasticized polyvinyl chloride); a rigid PVC, which is more durable and with better resistance to fire, heat, crack, etc.

Read more: PVC roofing sheet

This kind of PVC is a single-ply white membrane in roof covering of commercial and residential structures. The membrane is white. So it reflects heat and not absorb it. If you have a flat roof, PVC roofing cover is a great choice; because it’ll keep the room below cool and safe.

How to soundproof a suspended ceiling?

You can soundproof the ceilings either by installing acoustic insulations above your ceiling; or by using soundproof upvc roofing sheets. They are essentially self-insulating panels.

Which type of roofing sheet is best?

UPVC corrugated sheets and upvc economical sandwich panels are very durable and cost-effective. These roofing sheets don’t scratch. Color fading and roof tile crack cannot easily happen. They typically can last for at least 30 years – with least amount of repair.

What are the cheapest roofing sheets?

The cheapest material for a roof is bitumen roof sheets and fiberglass roof covering. But if you want to consider both affordability and durability, then you need to consider upvc roof panels that benefits you in almost all cases.

Sepid-Fam Varna is a professional manufacturing and Distribution Company: Producer of a new generation of uPVC sheets for roofing & cladding and sandwich panels – under the brand name “Polyroof Erica” – has started its activity since 2013. With cooperation of professional technicians and well-trained marketing experts in Iran, we ship our products to all over the world.

Our uPVC roofing sheets are widely used in various constructions such as: Canopies & Awnings, Industrial sheds, Villas, Houses, Livestock buildings, Warehouses, etc.

For more information about the technical specifications of sheets and profiles; please contact us:

Email: info@varna-group.com

Contact No: +98 912 962 9521