The pioneer of upvc rooftile manufacturing in Iran!

+9120465839

Sales unit Connection

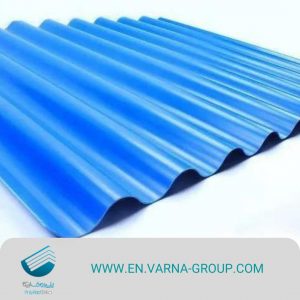

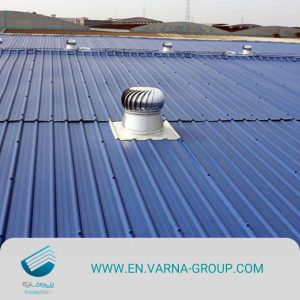

PVC roofing sheet and its strength and resistance, increase beauty and protection of your building. This type of roof has advantages that can be used in any place and with various applications.

In addition to covering the roof; it has also become common for cladding with PVC exterior walls.

It’s thermal and sound insulation and ability to withstand different temperatures – and its high impact resistance, has made PVC roof covering one of the most common way for roofing construction.

The roof is the main part of any structure and acts as a cover between the interior space and the outside world. While protecting the building from the elements, the roof sheets also can add to the beauty of your home. Choosing best type of roofing sheets to start constructing a building or renovation can be a big investment.

In this article we are going to cover both PVC roofing membrane and PVC roofing sheet. We look into advantages and disadvantages of PVC roofing sheets and other types of roof sheets as well.

PVC stands for Polyvinyl Chloride. It is made up of ethylene and chlorine which are derived from processed petroleum or natural gas and salt respectively.

This type of plastic is well known for its affordability and durability.

Best PVC roofing features include: self-washing, longevity, ability to withstand severe weather, easy and cost-effective installation and repair.

There are four different types of plastic roof sheets. Each of them has some specific properties that make them suitable for different construction applications. They include:

Corrugated plastic roofing sheets are clear and lightweight. They use for sheltering, protection or storage sheds; like farmhouses. Also for other sectors including: outdoor sheds, carports or canopies, etc. The ridges in the sheets make them sturdy and result in additional structural durability. So it makes them resistant to different weather conditions and external damages. Hence protects the interior sector of the structure.

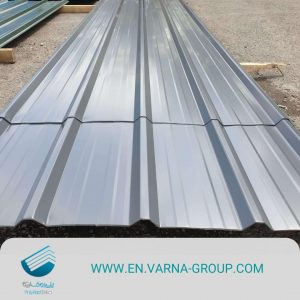

Being low maintenance, makes these flat coverings an ideal choice for: industrial sheds and warehouses, manufacturing and retail complexes.

These facilities consist of flat polycarbonate roof panels. They are incredibly durable and can withstand exposure to high and low temperatures.

PVC is one of the easiest roofs to clean. PVC roofing has many benefits, depending on the climate and application. One of the best roof options for greenhouses and other structures.

It is durable and lightweight; it can withstand almost high-temperature in summer and low-temperature winter without deforming or cracking. It can be applied with low-ridged meshes to prevent clogging, and scratching.

They are made from recycled plastic materials, which makes them an eco-friendly and sustainable option.

Acrylic roofing sheets provide optimal natural light transmittance. They are low maintenance and more affordable than traditional roofing materials. This type of roof sheets are generally impact resistance and have a light weight.

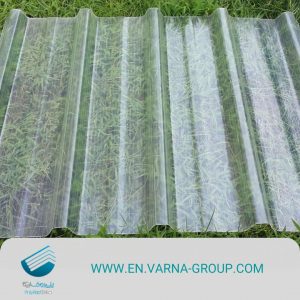

PVC sheets have Light transmission capability; but they have a high resistance to UV rays. Therefore they provide enough natural light illumination on roofs and side claddings.

Transparent PVC roofing sheets are an excellent option for the roof of many projects; such as: patios, greenhouses, barbecue covers, etc.

Terrace roofs should be covered with transparent sheets; because the plants need to get ample sunlight or else they will not grow well. For this matter, PVC roofing sheets can be transparent, or more obscure for added privacy. They let natural light in. PVC sheets are easy to clean, lightweight, flexible, cost-effective and easy to install.

Even in winter; you can sit underneath the terrace roof and have your breakfast and drink tea in the afternoon. You will feel the warmth of the sunlight on your skin, and enjoy being in nature under a protective roof. You also get vitamin D from Sunlight which is beneficial for your health.

Whether using polycarbonate roofing sheet or uPVC / PVC roofing sheet; all materials have their unique pros and cons that will benefit or damage your building.

Some of these materials will be perfect for your needs, while others might have one or two drawbacks; this means, there are some important factors to consider before making a purchase.

What is the standard size of a PVC roofing sheet?

Well, usually, the thickness of a PVC sheet varies between 1 mm to 3 mm. Its width can also be between 700 mm to 1200 mm. The length of PVC and uPVC sheets is usually made according to the customer’s order.

How about the price of PVC sheets?

PVC roofing sheets are resistant to scratch, unlike polycarbonate sheets. In terms of costs, PVC sheets are cheaper than polycarbonate.

Due to easy installation process of PVC roofing sheets, they are affordable in price, but also waterproof, flexible, light transmittance, etc.

So how much is PVC roofing sheets?

PVC roofing sheet costs about $5 to $7 per square foot. It could cost more or less according to the region.

There are many options for roof coverings in the market. We all know about shingle, metal, polycarbonate roof covering, etc. However, there is another useful material that provides high-quality and longevity for the roofs. It is called a PVC roof, a single-ply roofing membrane that is usually used on flat roofs.

PROS:

Some buildings, such as warehouses or industrial sheds, have significant amount of exposure to chemicals. But one of the advantages of the PVC roofing sheet is this: it is very resistant to this type of damage. Therefore, you can be sure that your flat roof system will be durable enough, even when exposed to harsh conditions for a long time.

Another benefits of PVC roofing sheet is its resistance to lightning and fire, (In addition to high winds). They are able to withstand high heat and flames without burning.

PVC roofing sheet contains special chemicals that allow it to be a self-extinguishing material. In fact, they burn slowly, hardly ignite and even extinguish the fire until the source is removed. This property can help keep the manufacturing facilities safe.

One of the main benefits of PVC roofing sheet is its resistance to UV damage. Over time, other roofing materials such as asphalt can become brittle and crack, but PVC roofing sheet maintains its integrity for years.

PVC is resistant to UV rays. Its white color also helps to reflect the sun’s rays. This will help save on your energy costs in hot weather. It is resistance to discoloration and protects the roof color of your building.

Thanks to the hot-air welded seams, the PVC roofing sheet is also resistant to strong winds. PVC sheets have also been proven to be highly durable due to their ability to withstand Category 3 hurricanes which are wind speeds between 110 mph to 130 mph.

If your building is exposed to strong winds and storms, PVC and uPVC roof sheets can be good choices for you.

With the hot air welded seams, this roofing materials are designed to let moisture out of building roof. So the building insulation does not condense moisture.

Also, if some parts of the roof sheets are damaged, vapor permeability helps to remove the moisture from the building. So there is no need to carry out immediate roof repair.

They are also resistant to mold and bacteria.

While other roofing systems require adhesives, tapes, and caulks to seal the materials together, heat-welded seams in PVC roofing create a watertight bond, making it very strong and durable. It is also very resistant to tears and punctures.

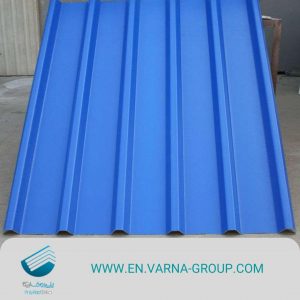

Another advantage of PVC and uPVC roof coverings; are their variety of colors and different thicknesses. This gives the clients more options. The thickness of the PVC sheets can range anywhere from 1.5 mm to 3.5 mm.

One of the important features of PVC roofing sheet is its lightweight. They are considered an easy-to-install roofing products. Because it is made of lightweight plasticized materials, its installation is easy and does not require any additional structural support. So it is ideal for buildings with low-slope roofs or flat roofs. (Widely used for suspended ceilings, too).

PVC roofing sheet is the third-most widely produced synthetic plastic polymer in the world. So, how long does PVC roofing last?

Due to its strength and durability, an average PVC roofing sheet lifespan is 25 years. The roof lifespan can be shortened or extended, due to variables like severity of climate, quality of installation, maintenance, etc.

PVC roofing is also environmental friendly and sustainable, even after years of service life. Plastic materials used for roofing like plastic pallets are eco-friendly and do not cause any harm to the environment. They are sustainable with the environment and are considered as one of the best choices.

Although plastic management is a global concern; and is causing water pollution each day, PVC materials for roofing systems are eco-friendly; and not a danger for the environment.

Elvaloy KEE (Ketone Ethylene Ester) is added to PVC sheets that increases their flexibility, toughness and durability. So the roof coverings are resistant to cold temperatures.

Due to this feature, it can be installed in a wide range of temperature conditions; it gives roof contractors more leeway in their works.

PVC and uPVC roof coverings are good insulators. PVC roofing sheet can improve roof insulation’s performance by up to 50 percent. They are resistant to heat, water and sound. In general, it can withstand chemicals, heat, water and sound. So, they can reduce your costs drastically.

Cons:

It has little resistance to very high heat. Since this PVC sheets are made of a kind of plastic, it can withstand a certain degree of heat; It starts to change shape more than this temperature. Of course, the self-extinguishing nature of this material has made this lack of tolerance, less noticeable at temperatures above 85 degrees.

PVC does not do well (as a roofing sheet) in very cold environments. Since it becomes brittle and can easily crack or shatter if walked on; you should prohibit walking on your PVC roof when the temperature falls below 50 degrees. (Any temperature lower than this, may damage the roof and make it useless).

The old roof membrane must be removed completely; so that PVC roofing sheets fixings be done overtop. Because PVC roofing system should – always – be installed on a clean smooth surface to adhere properly. Of course this extra work comes with extra costs. Therefore, choose a company that knows how to install them masterfully.

When burned; PVC can release toxic chemicals like dioxin which is harmful for the environment. It affects reproductive system, it may cause hormonal disorders and cancer; and damage the immune system.

Before choosing a roofing sheet material, you should always consider the slope or pitch of your roof. Considering the slope on the roof’s surface, may eliminate some potential issues in the future conditions of the roof.

All the roof tiles have a minimum slope requirement that distributes the weight of the roof evenly. The roof slope degree mostly depends on your geographic location.

Other details you need to consider while choosing a good roof tile are as follows:

Various materials are used in roof construction, such as metal, PVC, uPVC, polycarbonate, bitumen, etc. Each of them has a different shape, color and durability.

The life span of the roof is very important. Because roofs are always exposed to constant heat, rain and snow. Any weather changes, first affects the roof and then spreads to other part of the building. So choosing the best roof covering is very important.

Some of the best roofing sheet materials:

Bitumen roofing sheets are the most affordable roofing options. But just because it is a cheap roof sheet, does not mean it’s not as good as other products; because with proper care and installation, bitumen can last for decades at a lower costs.

Bitumen is unlikely to crack under pressure; however, it is more prone to small tears than PVC roofs. It has lower level of insulation and absorbs more heat in case of choosing a dark or black sheet color. Bitumen comes in a corrugated roof sheet or tile look too. Bitumen can also come in various sizes which makes it perfect for complex shapes.

Hardness of metal is not always a disadvantage; so if your building is likely to be affected by extreme weather conditions, it could be a good option.

Although slightly more expensive than bitumen, metal roofs are long-lasting and come in a range of coatings to suit your project.

Unlike PVC/uPVC and bitumen, metal roofing sheets are more difficult to shape or cut – But of course not impossible.

They are fire retardant, environmentally-friendly. They have longevity and offer a good UV Protection. Metal sheets are not recommended for roofing a flat roof.

Polycarbonate is an amorphous and transparent thermoplastic which has high impact strength. They are widely used in industrial and commercial sectors. Because of their transparency, polycarbonate roofing sheets are often used in swimming pools, gardens, patios, and greenhouses; the places where sunlight is required.

Polycarbonate roofing sheets are strong, plastic materials, stronger than PVC. They are lightweight and are fire and heat resistant. They also require low maintenance. This material can withstand high temperature and reflects UV rays. They offer variety of colors, but they have some disadvantages too:

Polycarbonates are still plastic. Therefore, scratches on their surface is inevitable, and the impact cracks will remain on the window. In some occasions this will require expensive repairs or replacement.

Due to their vulnerability to scratches, this roofs require a special cleaning; and this will reduce the lifespan of polycarbonate materials.

Polycarbonate roofs are artificial materials that endangers the environment, and it combines with phosgene and chlorine. These chemicals can cause health problems in humans.

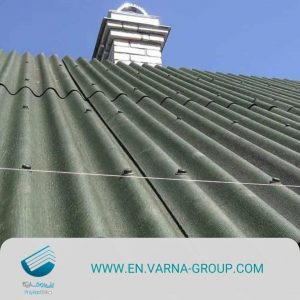

Unplasticized Polyvinyl Chloride (uPVC) is now one of the most recommended materials for roof sheeting.

Trapezoidal, sinusoidal roof sheets, cladding profiles; sandwich panels, etc. These are just some products in our Company, Sepid Fam Varna. They are all from uPVC materials and have the following advantages:

PVC roofing is often used for carports and porches, as it allows light to penetrate through. As we mentioned earlier, PVC sheets are lightweight and a great material for many DIY projects. PVC roof sheets are fire-resistant and easy to install, making them great for use in offices and modern homes – as a dropped ceiling.

But it might not be the best option if you need a good material for insulation; however, for most projects that you need light, such as a carport, it can be a good option.

Flat roofs are mostly used in commercial buildings. Of all types of roofing membranes, three main varieties are more important: EPDM, TPO and PVC.

One of many benefits of PVC roof membrane is that: It usually has a lifespan of at least two decades. Here’s what you can do in order to extend PVC roofing lifespan:

One of the primary advantages of PVC roofing is that; it is strong and durable. it can last for more than 20 years. So it is cost-effective, meaning: it can save a considerable amount of money on roof repairs and maintenance expenses. So you have more money to invest in your business. Properly maintained, PVC roofs can be preserved even longer.

A common issue with flat roofs is poor drainage. Resolving it can help in preserving the lifespan of your PVC roof. This requires stopping ponding water.

If you fail to address ponding water, it can result in water seeping, which leads to severe water damage and expensive bills. Unfortunately, most of the time damage from ponding water will get worse and result in growing mold and rots.

Another important factors in preserving your PVC roofing membrane is: inspecting flashing and seams after a rainstorm.

Before leakage occurs, you should consider worn places or damages. Otherwise damage increases and the lifespan of your roof membrane will be shortened.

What are the differences between fiberglass roofing panels and PVC roof panels?

Fiberglass reinforced panels, or FRP, are made of strong polyester resin reinforced with fiberglass. They are used on walls and ceilings and can be installed on many solid surfaces.

PVC roof panels, or plastic roof panels, are made from polyvinyl chloride. It is a thermoplastic material and is available in corrugated panels. But the more popular type, is used as flat panels.

FRP has higher strength and hardness; however, PVC has longer lifespan and is low maintenance. It also installs quickly and easily and has a convenient transportation. Therefore it saves your construction costs.

PVC roofing sheets are more flexible but fiberglass is more rigid. So for installation of curved roofs, the flexibility of PVC sheets will be a better fit.

PVC panels are a protective layer in claddings and ceilings of residential and commercial buildings. PVC sheets are durable and strong and lightweight. They can be built in different thicknesses, lengths and colors.

False ceilings are also known as dropped ceilings or suspended ceilings. They are secondary ceilings with shiny surfaces that are hung below the main ceiling with suspension cords.

They improve not only the aesthetic appearance of interior sectors, but also act as heat insulators too. They can hide ducts and other hanging elements on the ceiling. They reduce sounds and act as an acoustic barriers.

PVC can be used in open spaces, like Balconies. Also bathrooms, basements, living room are some common places to be used – to increase the aesthetic of the interior design of your house.

PVC ceiling panels have some disadvantages too. For instance; with different designs and colors, PVC false roofing might seem attractive, but it has a plastic appearance after all; so to some, it might not have an aesthetic appearance look and it is considered a disadvantage.

Moreover, in the manufacture of PVC materials, chlorine is used. When burnt, PVC becomes toxic, due to release of chlorine gas. So you need to be careful when installing a PVC ceiling in the kitchen.

Fibre roofing sheets or fibre-reinforced polymer or Fiber PVC roofing sheets, are the result of polymer and fibre being reinforced together. The polymers used in the composition could be epoxy or vinyl ester. But the fibre could be glass or carbon. These combination together can result in highly strong roofing sheets with great elasticity.

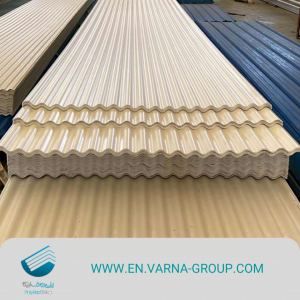

Corrugated sheets have repetitive folds on their surface. Because of their rippled structure, they are stronger. Its unique shape has increased its utility and durability.

The biggest advantage corrugated sheets have – over flat sheets – is their extra strength. More rigidity and strength in bending, prevents from sagging, adding more support to your roof. It ensures that your roof remains strong and rigid; so it extends the lifespan of your roof.

Corrugation allows quick and easy drainage of rainfall off the roof.

In different weather conditions, the corrugations have space for the movement and so the material is not damaged and will remain leak free.

With holes drilled through the crown of the corrugations, the rainwater is less likely to seep through the roof.

Corrugated PVC roofing sheets are an excellent choice for roofing structures where durability is important; and when you need natural light to pass through the roof. They are made with the help of innovative synthetic plastic polymers.

If you need sun light to pass through your roof, PVC Corrugated Sheets are a good choice. Corrugated plastic sheets which are a kind of PVC material, can be a replacement sheet for your new canopy, patio, greenhouse, sheds, etc.

Corrugated PVC roofing sheet are also a good and cost effective choice for residential areas. They can also withstand harsh weather. Clear and lightweight corrugated PVC sheets are offered in different thicknesses and lengths. They are anti-scratch and easy to install and use.

Corrugated PVC panels are widely used in: Car ports, sheds, pergolas, stables, farm, walkways, etc.

It can be as replacement sheets for older roofs as well. (As roofing and cladding).

PVC sheets can be a bit brittle, when fixing. It can break and split when being fixed down. A corrugated sheet fixings have a seal which clamps to the plastic, spreading the load and reducing the chance of Splitting.

The installation process can be applied to canopies, awnings, gazebos, sheds, etc. It includes a checklist and important warranty details.

In order to install PVC Corrugated roofing sheets, you need following materials and equipment:

Here are the steps:

Corrugated fiberglass or PVC roofing, is ideal for greenhouses, patio, sheds, etc. PVC roofing will need to be cut so that; it can be installed correctly and can, protect the structure.

You can obtain PVC roofing sheets in multiple lengths. This way you reduce the number of cuts to make the sheets fit for your project. Note that you cannot avoid cutting some sheets during the installation process. Use the proper tools to cut the corrugated roofing to avoid damaging the sheets.

Cutting PVC sheets can be used by hand or power saw. You should Use at least a 40-tooth carbide blade for a cleaner cut.

PVC Roofing sheet Cutting Tools:

Here are the steps:

Step 1

Set the corrugated sheet on a flat surface and measure its length. Cut it with scissors or a craft knife. To do markings on both ends of the sheet, draw a line between them with a straightedge.

Step 2

Place the sheet over the flat surface’s edge and align the line. If your material has more than 3 feet of hanging on one side; with help of a coworker, keep it in place while you cut. While working, you need to use goggles.

Step 3

Set the depth of cut on a circular saw to its maximum depth. A standard, carbide-tipped blade will do. Holding the blade guard open, with other hand, keep it stable and begin cutting along the line.

Step 4

The machine will continue to cut through the material. When you’re ready to cut release the safety with your other hand – press the roofing against a flat surface. Minimizing the vibrations, it will help to minimize chipping and binding.

Step 5

Cut slowly and gradually from one end of the line until you reach to the other side – Keep on cutting. Note that when you trim up the edge of an off-cut; the cut edge needs to fall away before you pull the material away – you do not need to do anything.

FAQs

Composite, PVC and uPVC roofing sheets are the latest roofing materials.

Maybe you think PVC coverings are considered cheap plastic roofing sheets. Although for a flat roof, PVC roofing sheet is a good choice, but the cheapest material for roof coverings are bitumen sheets; however, when performance and lifespan are considered, then uPVC roof sheets are still a highly cost-effective option.

Maybe you like to have an open terrace garden; however, due to excessive sunlight or heavy rain your plants might get damaged. So covering your terrace with durable PVC roofing sheets, might be a good choice.

It’s said that walking across PVC roofing will cause it to crack, but it is strong enough to sustain a person’s weight; especially if the decking underneath is strong enough. But better not to walk on PVC roofing, the roof becomes slippery when cold or wet, which makes it much more likely for you to fall.

Generally speaking, PVC installation is not a DIY project and it is better to allow a professional to install it; however, if you have heat-welding experience, you may do it.

Although they are used for similar purposes on low-sloped roofs, they have some differences in their makeups. TPO coverings are made of an ethylene or polyethylene thermoplastic which have lower cost. PVC is made from vinyl chloride monomers. For more flexibility, they add plasticizers which make them easier to install.

Though it is not the only factor, but the important one; and that is the size of the roof. Different colors and patterns can change the price of PVC sheets too. White color is the most common, as it is reflective and improve energy efficiency in the building.

Yes, PVC is made of a waterproof material that makes walls and ceiling panels resistant to water. The PVC panels are best suited for cladding the ceilings; for instance: They are mostly used for bathrooms and garages – to prevent dampness.

PVC false ceiling design gives a beautiful look to the environment of the structure. Such as: Schools, Restaurants and food processing facilities, hospitals, cafeterias, etc. In addition to its high chemical resistance, PVC sheets are also widely used due to their high resistance to fire.

Generally, PVC roofing sheet is resistant to UV rays and will not immediately deteriorate in sunlight; however, constant exposure to sun and very high temperature, can damage the sheets more easily. The average lifespan of a PVC roof sheet is between 20 to 30 years.

Flat roofs are ideal options for projects that require low maintenance. Flat roofs are a low-cost alternative to pitched roofs. They are quicker to install and can be maintained easily when required. That is where PVC roofing membrane comes along. It is the best choice for flat roofs and requires minimal maintenance.

PVC roofing (membrane) which is made of polyvinyl chloride; is a single-ply roofing solution used on roofs that are flat or low sloped. PVC or polyvinyl chloride, is the third-most widely produced synthetic plastic polymer.

uPVC sheets are more durable and stronger than PVC; furthermore, the top layer in uPVC sheets is covered with PU (Polyurethane) – which shows significant resistance to sunlight. (Anti-UV).

uPVC roofing sheet is more resistant to cold and heat than PVC sheets. In terms of cost, it can be said that uPVC have reasonable prices – although higher price, but lower maintenance cost. PVC and uPVC sheets are both environmentally friendly.

Read more: UPVC roofing sheet & its application

Sepid-Fam Varna is a professional manufacturing and Distribution Company: Producer of a new generation of uPVC sheets for roofing & cladding and sandwich panels – under the brand name “Polyroof Erica” – has started its activity since 2013. With cooperation of professional technicians and well-trained marketing experts in Iran, we ship our products to all over the the world.

What we Offer at Sepid-Fam Varna

Our uPVC roof sheets are widely used in various constructions such as: Canopies & Awnings, Industrial sheds, Villas, Houses, Livestock buildings, Warehouses, etc.

For more information about the technical specifications of sheets and profiles; please contact us:

Email: info@varna-group.com

Contact No: +98 912 962 9521