The pioneer of upvc rooftile manufacturing in Iran!

+9120465839

Sales unit Connection

home » article • دستهبندی نشده » What is the best anti corrosion roof sheet in 2024?

First, let us be clear. This article is not about showing some tools or methods that can treat corroded roof sheets. Our main goal in this topic is introducing a new type of anti corrosion roof sheet that rarely rusts or gets damaged. A material that has the ability to perform as a rust-proof, waterproof and corrosion-resistant coating with lifespan of about 50 years.

Why is it so important? Because despite the unprecedented price hike in 2024, especially in the construction materials market, people’s demand for buying anti corrosive roof sheets has increased. By purchasing anti corrosion roofing sheets, in addition to quality assurance, you will no longer have to worry about renovating, roof repairing and maintenance cost in the years to come – Even if you live in villa and coastal areas.

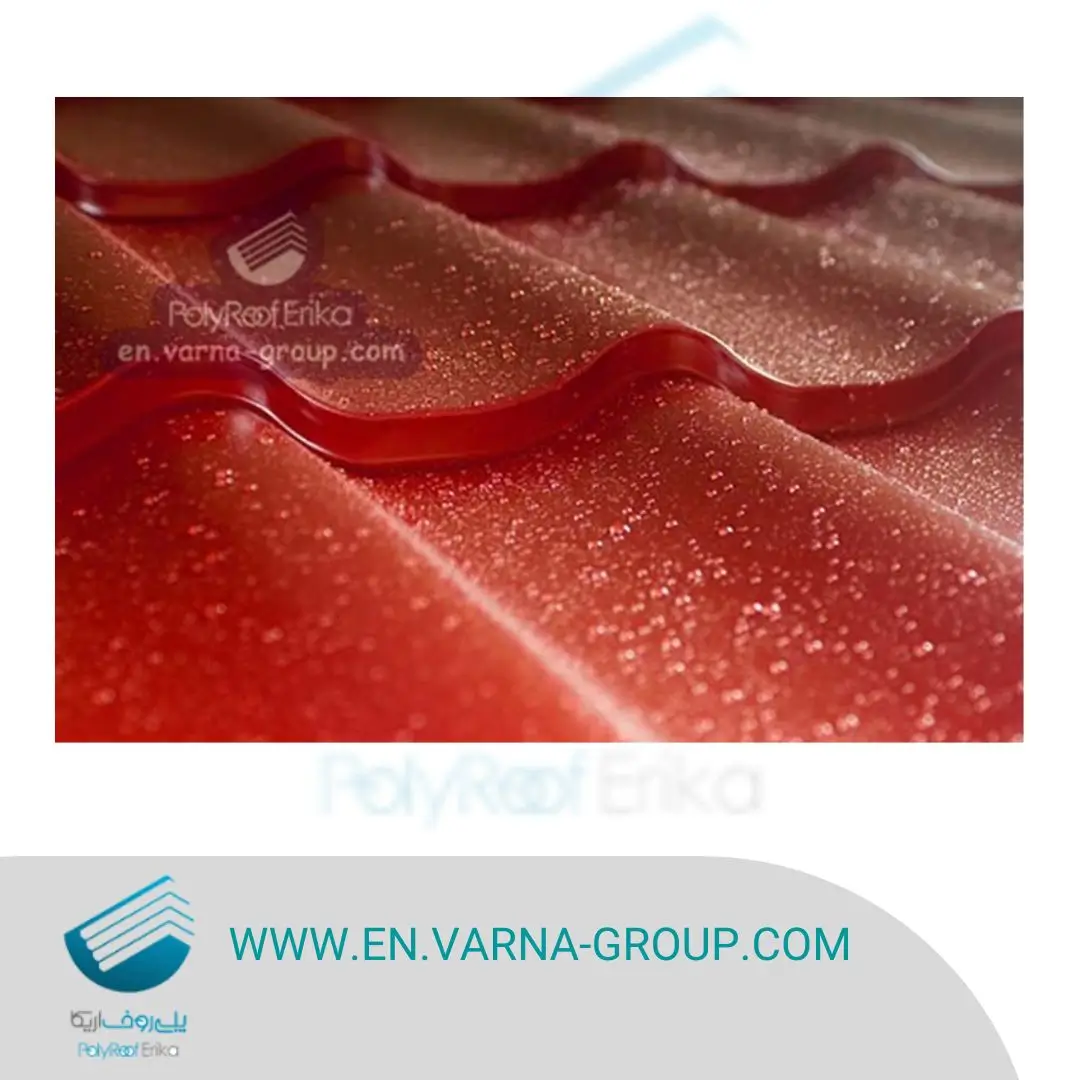

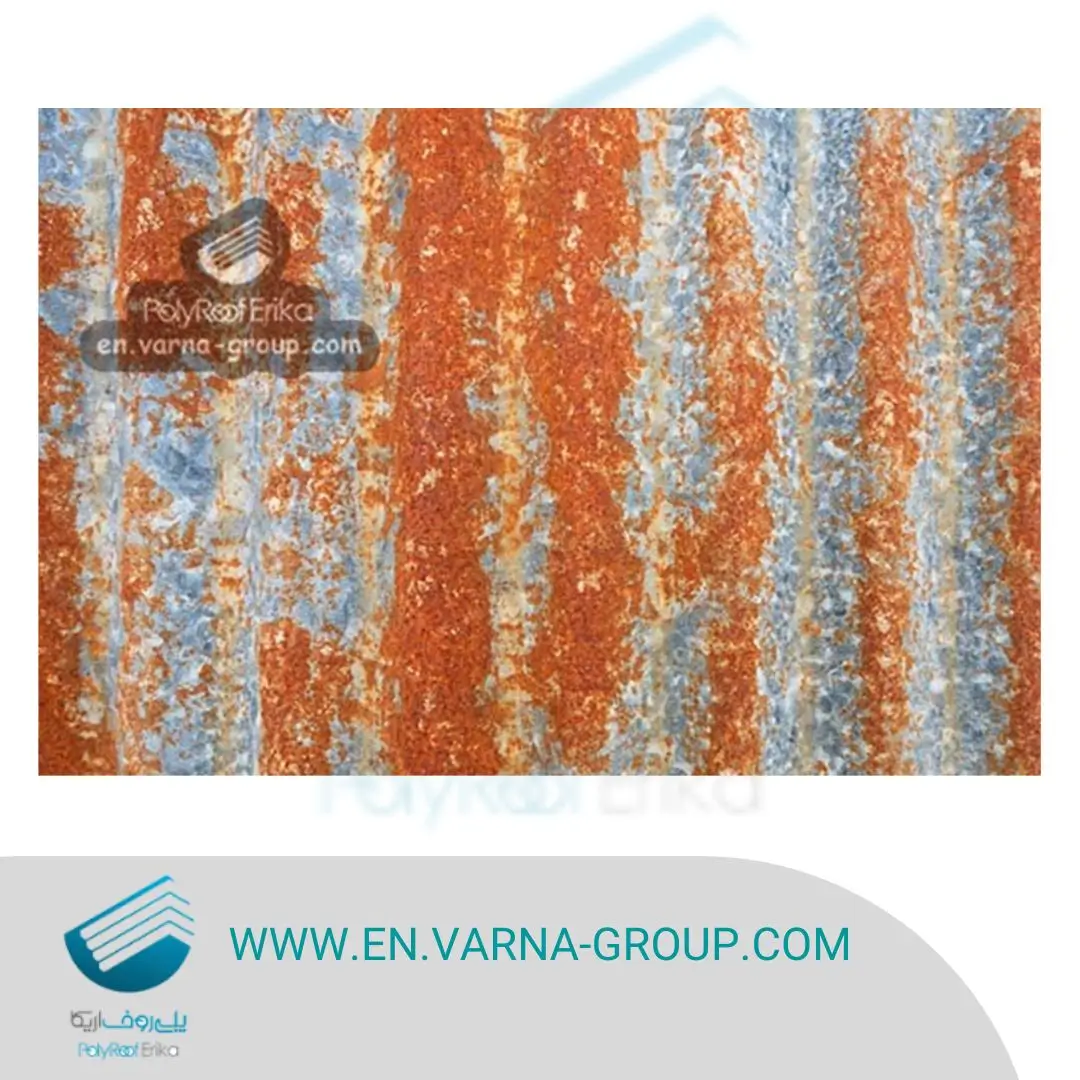

Oxidation prevention is an important factor for a roof not to corrode. If you look to galvanized roofing, you will find out why they rust and their color changes. Because the layer of zinc protection can be easily distorted. Due to the damage of the protective layer, it cannot prevent your roof from corrosion. So, the roof is easily exposed to UV, water and moisture. This will accelerate the corrosion process.

Another factor that can help to make the sheets corrosion proof are the mechanical properties. It means how a roof can endure impact. Because strength and toughness can make them less susceptible to corrosion.

Paint or the protective coating also can make an anti corrosion roof sheet. For instance, PU (Polyurethane) layer on UPVC sheets, provide a strong barrier and also an anti-microbial membrane in most corrosive environments.

While walls and roof of your working place i.e. industrial shed might be in danger, an anti corrosion roof sheet is a huge life saver. Why? Because all your surroundings in these places are exposed to chemical gases and toxic vapours. Now if you have already protected your skin and health against it, good for you. but what are you going to do to protect your roof and cladding? And to prevent from damaging gases and vapors that can contaminate the air at your workplace?

Our anti corrosion UPVC roof sheet can do it perfectly for you. As it does not react with air, water and chemicals. That is the major advantage of uPVC over galvanized roofing. Because of this anti corrosive properties, UPVC roof sheet is way more cost effective than any other materials specifically in coastal and humid areas. That is why you will see uPVC pipes in almost every industry. Not only this, but corrosion proof UPVC sheet is also resistant to acids, alkalis and salts – whether a salt storm or sodium chloride which you use in your food. That is how they can remain durable and their color will not fade away over time.

Elastomeric insulation foams are one of the most effective ways to make an anti corrosion roof sheet. Closed-cell structure of elastomeric foams can reduce moisture and is a hydrophobic roof that is highly resist to corrosion.

This insulation foam is used only in uPVC roof sheets for flat and gable roofs. They are also known as economic sandwich panels or Eco panels which we manufacture at Sepidfam Varna Company. It is covered in 4 layers with polyurethane coating. This helps the roof sheet not only be an anti-corrosion material but also anti-UV, and remains strong and stable in the most difficult weather conditions without color fading. For more information on our new and practical products, please contact Varna team.

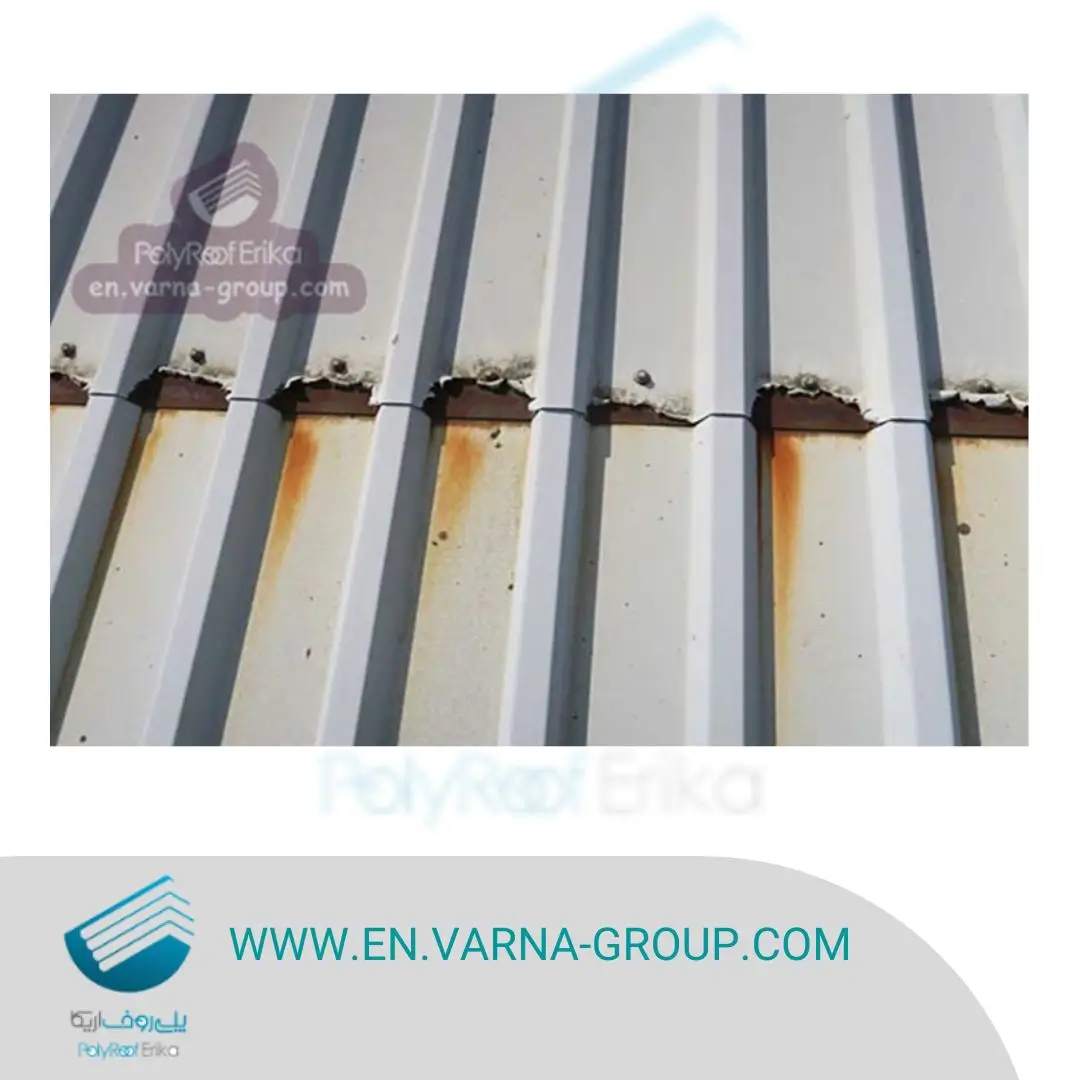

Let’s face it, all stainless steel or galvanized or color coated metal roof sheets, rust and corrode, it is just the matter of time. The protective coating on the metals can only delay the development of corrosion and rot. Galvanized roof sheet is not anti corrosion because it is made of iron which is exposed to rain and moisture. They are also susceptible to rust due to the electrochemical process. Rust is another form of corrosion. Other types of corrosion in metal roofs happen when a roof sheet goes under pressure of another metal sheet. This increase the chance of stress corrosion cracking. That is why overlapped metal layers have the highest possibility of corrosion.

How to make an anti corrosion roof sheet or at least reduce the corroding areas? If you still insist on using galvanized or metal coating, you can combine them with UPVC panels. Use uPVC roof sheets or elastomeric sandwich panels in areas where there is the highest possibility of corrosion or damage due to impact, pressure, humidity and temperature changes. It will provide not only a flexible seal for sensitive areas, but also help the rigidity and longer life of your roof.

Remember galvanized roof panels can move with temperature fluctuations. These movements even in low frequencies can cause microscopic crack and make a better way for water and moisture to flow through – what you do not want to happen. But with anti corrosion UPVC roof sheets your house will be safe from any rust and corrosion or any other environmental and chemical factors.

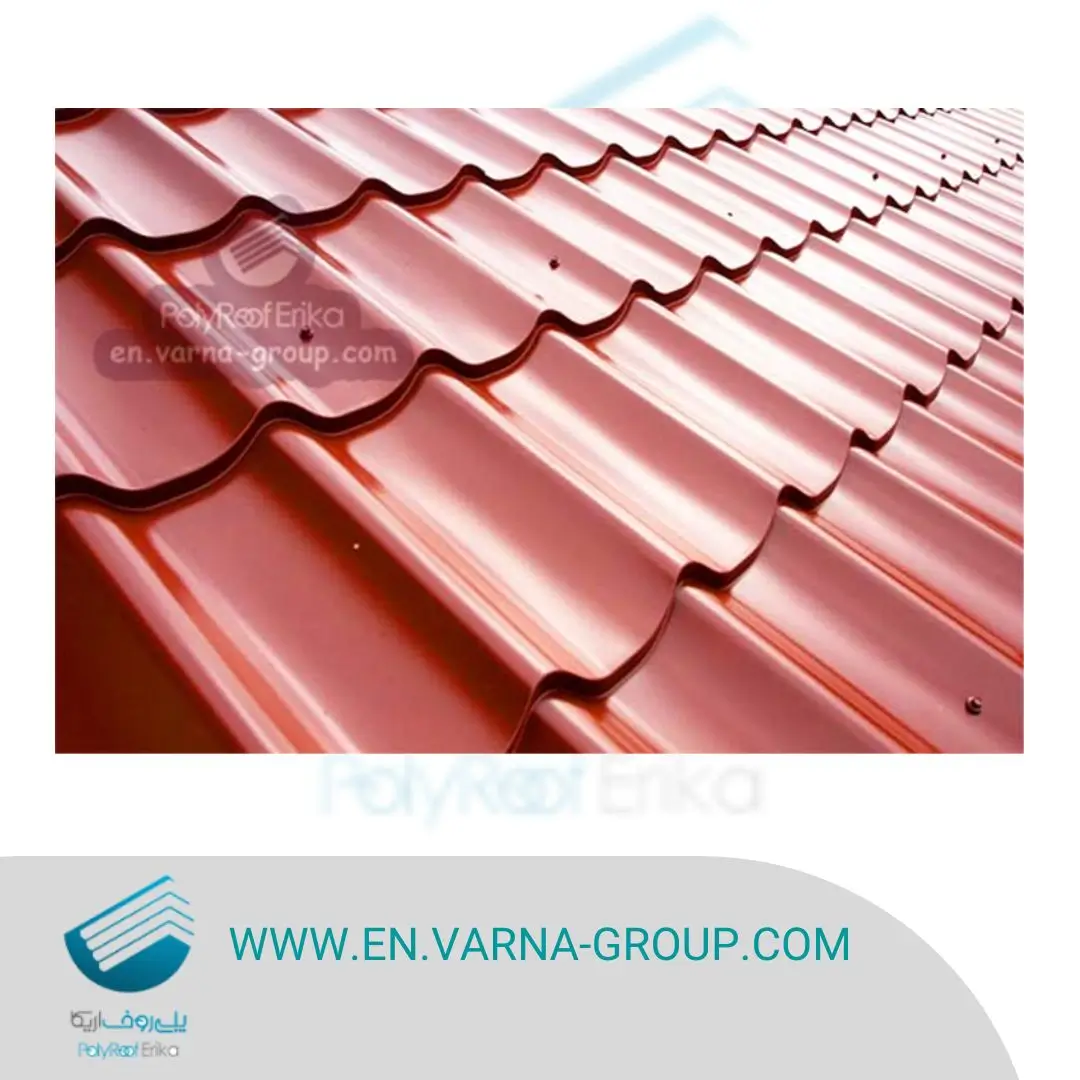

Unplasticized polyvinyl chloride or uPVC is a rigid form of PVC; a popular thermoplastic construction material. Although they are hard, yet are flexible and have the capability to bend and make the shape of an arch for constructing modern and schick roofing designs.

That is the same material which are used for windows, doors, pipes and gutters. Manufacturing in different colors, lengths and shapes, UPVC can be drilled and cut to one’s desired designs. Since UPVC roof sheet is anti corrosion material, it does not require insulation or sealing and can be easily cleaned with water or rain – in case of outdoor usage.

The protective coating of polyurethane in uPVC roof panels is a strong barrier against moisture or UV exposure.

UPVC has been replacing traditional building materials in many construction projects. An anti corrosion roof sheet and excellent alternative for wood, metal, FRP, ceramics, etc. Some of the best features of roof and cladding in Sepidfam Varna are as follows:

For further information on our product prices and the updates, please contact Spidfam Varna consultants:

(+98) 912 0465 839

varna.group.upvc@gmail.com