The pioneer of upvc rooftile manufacturing in Iran!

+9120465839

Sales unit Connection

home » article • دستهبندی نشده » Galvanized roof Sheets; Pros & Cons, Installation, Price

Galvanized roof sheets have been widely used by various manufacturing Companies. The process of zinc metal on steel or iron sheets can be applied either by hot dipping or electroplating method. This will make a physical barrier which can almost minimize the penetration of sulphide and chloride ion.

But can galvanized sheets protect your roof from corrosion and rust in the long run? Are there any other panels that can protect your roof better with a lower price? In this article, we will answer these types of questions.

Before galvanizing process, there are some steps to prepare the steel sheets. First the panels must be cleansed in a degreasing solvents. Then they have to be fluxed with a purifying agent such as zinc-ammonium chloride. And then be immersed in molten zinc – which is called hot dipping – to be coated completely usually in 450 °C. The aim of this process is to prevent rust on the steel and have a longer lifespan.

Another types of roof galvanization is that the sheets do not need any molten vat of zinc. Instead it is done by an electrolyte solution through an electric current to transfer zinc ions to the metal.

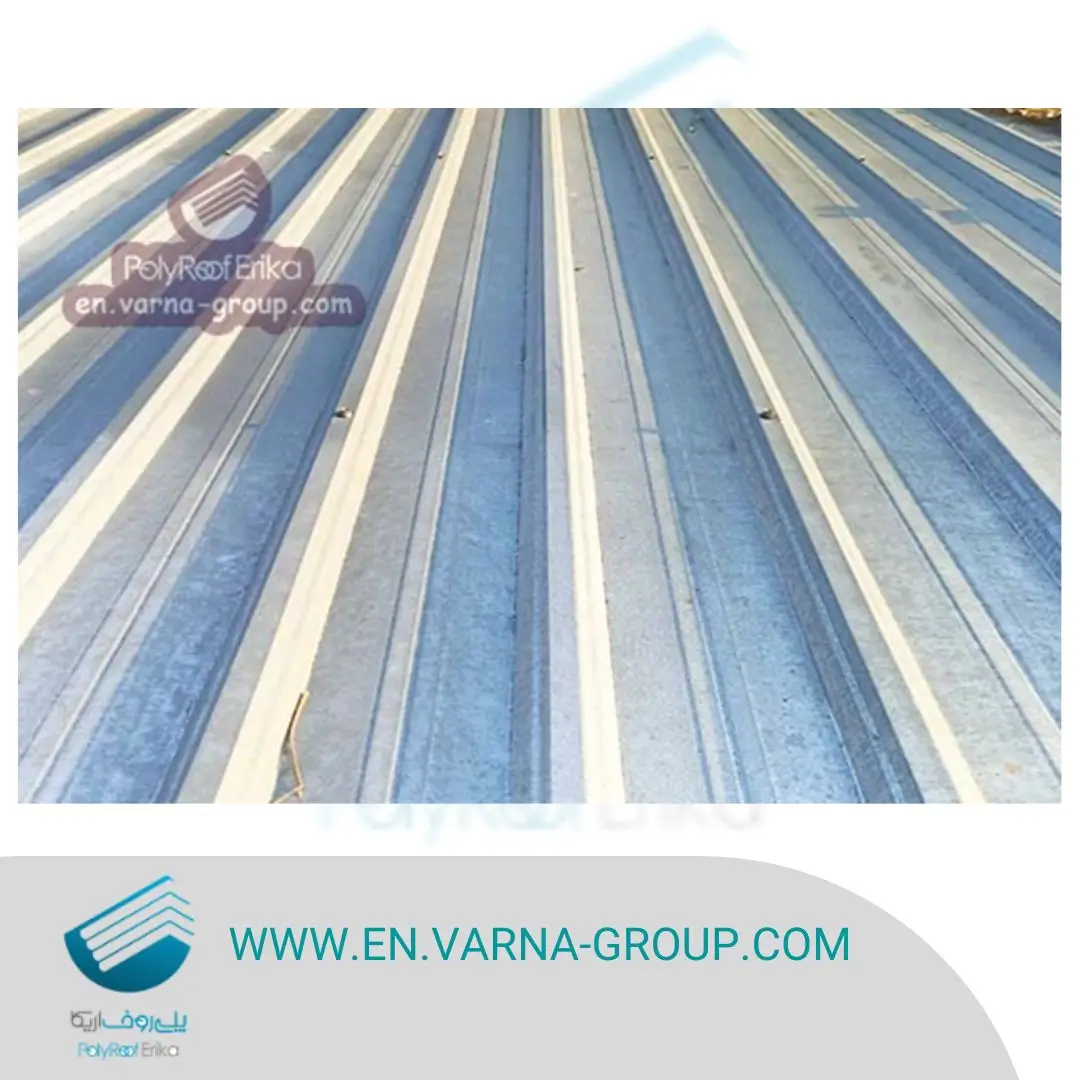

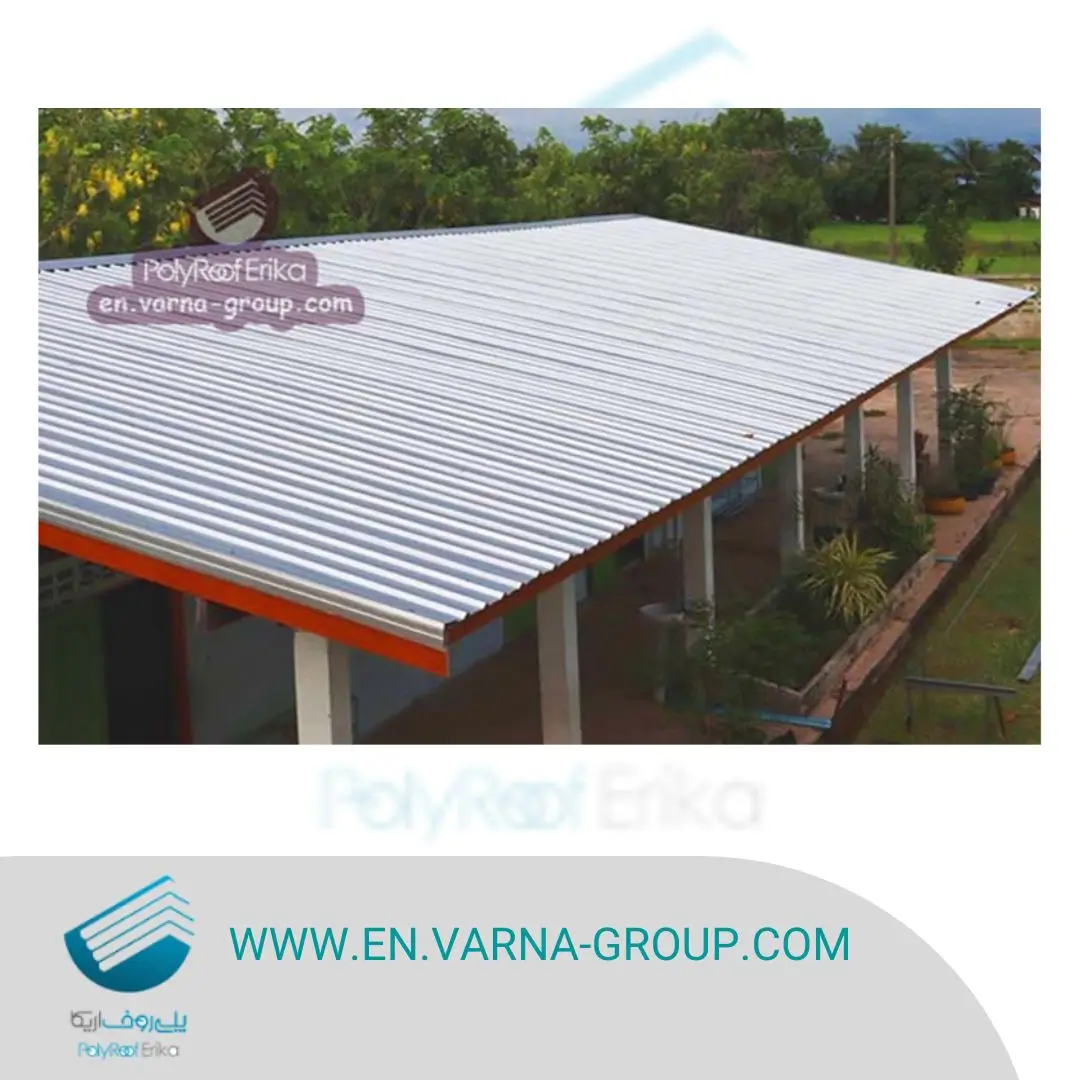

There are some forms of steel sheets in galvanized roofing such as corrugated, flat, tiles or shakes. Depending on the usage, weather changes and design of the building these forms can vary.

When it comes to the width of galvanized sheets, your roof is mostly dependent upon the material, manufacturer and gauge of the panels.

The lower the number of a gauge, heavier the gauge is. For instance 24 gauge is heavier than 26 gauge. Although lighter metal or galvanized roof sheets are 10% to 15% cheaper, but do not resist well against snow loads or in high winds and storms. Another factor is the spaces between the purlins. If the space is wider in your roof you need to go for heavier galvanized panels. You can choose very light as in 29 gauge or the heaviest which is 20 gauge. But generally in most cases 24 or 26 gauges are the common types used. Between the 2 ranges you can also save money up to 30% when choosing the 26 gauge thickness sheets. Among all the metal roof types galvanized and after that galvalume panels have lower prices.

Metal sheets that are offered in the form of galvanized or galvalum are beautiful and have an impressive appearance. However with the significant advantages of these roofs, comes the disadvantages and problems that should be paid enough attention to – especially for owners who intend to buy durable and long-lasting roofs. Here are some of the most important pros and cons of galvanized roofing:

There are different factors that can affect the price of galvanized roof sheets. Such as: the material type and paint finish, installation, sizes and thickness or gauge of the steel, price fluctuation of metal market, etc.

Important tips before installing galvanized roof sheets, is the overlapping process and screwing metal roofing. Before overlapping corrugated roof sheets, we need a double sided butyl tape at the overlaps. On the second wave the sealant tape should be applied. Overlapping process can decrease the width of panels. For instance, 37 inch width of galvanized sheets can only cover 32 inch of your roof width after side lap.

To fasten metal roof screws properly, you need to place them on the wave of the sheets. This will lead to the better water tight roof rather than screws applied on the valley of the panels. Besides, the line of screws is also important. Each 1 mm2 roof panel consists of 4 screws in a direct raw line which is placed at the wave of the galvanized corrugated sheets. It is important to note that screws must be applied on the overlapped panels. However the spaces between screw lines depends on the location of corrugated roof sheets, climate changes and the roof manufacturer. Installing galvanized roofing is better to be done by experienced roofers or contractors rather than DIY.

According to the important points mentioned in this article; among the most important problems of galvanized or metal roof sheets is the high probability of rusting and corrosion – especially for damp or coastal location. Here, we suggest purchasing the new generation of UPVC sheets produced by Sepidfam Varna factories. You can literally find out the meaning of an anti-corrosion, waterproof, light and strong roof. In addition to lasting 40 to 50 years, UPVC sheets can be installed on most roof coatings. It can be implemented with a cheaper price than metal roofs in terms of material, installation, infrastructure and maintenance costs.

If you are considering a new roof or wall claddings for your home, office, industrial shed or warehouse; consider UPVC coatings advantages Vs galvanized roof sheets. Allow us to guide you through this journey and protect your property. For further info on our updated prices and new products, please feel free to contact our consultants at Sepidfam Varna Company:

(+98) 912 0465 839

varna.group.upvc@gmail.com